A mechanics creeper (also called a car creeper or creeper trolley) is a simple yet quite popular device used in the maintenance, inspection, and repair of vehicles.

The mechanic’s creeper is basically a flat surface that sits just a few inches off the ground. Supported by wheels that move in 360 degrees, a mechanic can use the creeper to slide under vehicles.

The mechanic lays on the surface of the car creeper, much like lying on a bed. Using their feet, they can push the creeper in any direction on the floor.

This allows for a full inspection of the underside of a vehicle without the mechanic having to use his or her hands to propel the creeper.

Table of Contents

What are Car Creepers Made of?

A mechanics creeper is made from several different elements.

Today, steel is the most common material that makes up the frame of a mechanics creeper.

The steel provides the strength needed to hold the weight of the mechanic as he or she works under the vehicle.

When they were first invented, wood was the most common material used for the bench. Today, it is PVC.

This is because PVC is lighter, stronger, and more durable compared to wood. It is quite resistant to abrasions and easy to maneuver.

As an alternative to PVC, polypropylene is used when creating the molded benches or bodies of the mechanic’s creeper. It is tough, durable, and quite flexible.

A typical mechanic’s creeper will have its bench covered in vinyl with some padding underneath for comfort. Vinyl will cover both the bench and headrest.

Finally, a powder coating will cover the steel frame to protect it from corrosion, chipping, and scratches.

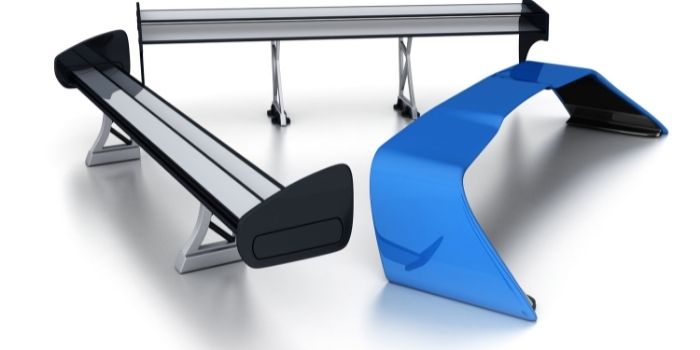

What are the Different Types of Car Creepers?

Although many people believe that mechanics creepers are mostly the same, there are some popular variations.

1- Adjustable Headrest:

This is essentially a standard mechanics creeper where the headrest can fold up at an angle.

This allows for the head to be placed at an angle as opposed to perpendicular to the floor.

There is an adjustment that can be made to set the headrest at the desired angle.

2- Bone-Shaped:

This is a mechanics creeper that is normally crafted from one piece of molded polypropylene copolymer.

It has four large caster wheels that are extra wide. This allows the creeper to move along rough or uneven surfaces such as gravel, sand, or broken concrete.

This type of mechanics creeper is often used on the road and not in a typical auto shop.

3- Contoured:

Instead of a flat bench, this is a creeper with a shape contoured to fit a typical person lying down.

Unlike a standard mechanics creeper, there is usually no padding except for the headrest.

Contoured creepers often have tool trays, places to keep parts, and a handle for easy carrying when not in use.

4- Folding:

This mechanic’s creeper is crafted in two parts and connected by an extended frame.

This version consists of a steel frame, padded backbench, and headrest covered in vinyl.

However, this creeper has a split back, allowing one section to rise upwards and become a seat.

This allows the mechanics’ creeper to be used as a standard seat or bench for sitting upright.

When used as a bench, the top section folds down into place.

To go from a standard creeper to a seat, you must release a lock, raise the seat, and release the lock lever so it can be put into place.

5- Raised Sides:

A standard mechanics creeper with raised sides that allows for easier maneuvering.

This allows the use of the hands and body to shift the creeper while being propelled by the feet along the floor.

How to Use a Creeper for Working Under Cars?

To use a mechanics creeper the right way, the first step is to raise the vehicle to a height where the mechanic can slide underneath.

Remember to use a pair of secure stands to support the vehicle once it is raised. The stands must be positioned on the axle so they are secure and will not slip.

Once the vehicle is secure, put the creeper in position near the vehicle. Make sure the surface is level if you are using a standard creeper.

A bone-shaped creeper can be used on rough surfaces. Now, sit on the bottom end of the creeper and lay your head back on the headrest.

Your legs should extend away from the creeper to the point where your feet can propel the device.

Now, you can use your feet to propel the creeper and yourself under the vehicle. Have your tools and parts within easy reach.

If you decide to take a break, roll out from under the vehicle, get up from the creeper, and either slide the creeper back under the vehicle or hang it out of the way. This prevents stepping and slipping on the creeper.

When finished, store the creeper by standing it on its bottom end or hanging it on the wall.

Considerations when Buying a Creeper and Maintenance

The main consideration is that the creeper is strong enough to hold your weight. So, you need to check to see if the creeper has the proper weight capacity.

A few other things you will need to look at are…

a) Changing Positions: If you frequently change from lying down to sitting up when working on vehicles, then a folding creeper is the best design for you.

b) Comfort: The creeper needs to be comfortable, especially if you plan on working for several hours in your vehicle.

c) Dimensions: While weight capacity is the most important, size is right up there as well.

It should be broad enough to sufficiently support your back and arms. It should be the right length which is from the top of your head to your bottom.

d) LED Lights: For areas that are poorly lit, LED lights are a great addition to the creeper.

And last but not least is the price. Once you have found the right creepers for the job, choose the one that offers the best price.

Maintenance is relatively simple. Wipe down the creeper after every use.

Next, inspect the creeper to see if there is any wear or damage to any of its parts, particularly the wheels. Damaged mechanics creepers will have to be replaced.

Finally, sweep the floor and keep the area clean.

Based in Orem (Utah) John Paterson graduated from Utah Valley University and has begun writing in 2009. He has a large wealth of experience in writing articles related to cars, automotive repair, wheels, cleaning/maintenance, and much more. He has also written instructional articles in a similar niche for a few online publications as well. Currently, he works as a mechanic in his personal garage shop where he loves serving his countrymen from his heart.